An Exclusive Interface with Mr. Christian Tanner, COO, Mayr Power Transmission

IU. Which segments of the Indian automation market show the greatest potential, and how is Mayr® adapting its approach to address them?

Three key trends are shaping the Indian automation market. First, the rise of robotics and autonomous systems in various applications. These systems require precise power transmission and unwavering safety – exactly what our products deliver. Second, the growing importance of data. Smart production environments and the IoT are no longer just concepts; they are a reality. This creates a demand for intelligent, network-ready components that do more than just function—they communicate. This kind of real-time data enables the mentioned smart, efficient environments, but also opens the door for predictive maintenance and more sophisticated decision-making processes This brings us to the third pillar: Artificial Intelligence. AI will further streamline workflows by leveraging this data. Our approach is to develop smart components and solutions that seamlessly integrate the drive train into the data network of a connected shop floor.

IU. What is your vision for Mayr®’s presence and growth in India over the next five years?

As a family business, we are committed to sustainable growth. Our subsidiary is set to grow to 20 employees over the next 3 years. Their development is particularly important to us, as highly motivated and well-trained employees are one of our key success factors. We see ourselves as a reliable partner for emerging high-tech industries such as robotics and automation. Our innovative products add safety and reliability to systems and machinery, which is exactly what is needed in these sectors.

IU. What has been the key factor behind Mayr® power transmission’s global success in safety brakes and torque limiters?

Mayr® power transmission is one of Germany’s most established and innovative companies in power transmission. We make no compromises when it comes to safety. Only top-quality products can guarantee that people are not injured, and machines are not damaged during operational malfunctions, collisions, or other hazardous situations. The safety of employees and machines is our motivation to consistently deliver the best and most reliable torque limiters, shaft couplings or safety brakes.

Highly trained and motivated employees are also key to our success. The long-term success of Mayr® India is built on a vibrant, close-knit corporate culture, adopted from our German heritage and deeply rooted in our global operations. This value system ensures that the company is not just a high-quality manufacturer but also an empathetic and supportive employer.

IU. How is Mayr® responding to the growing demand for automation and smart machinery?

We believe the key to innovation is looking beyond our own industry. Industries like stage technology and amusement parks, which have incredibly high safety standards, offer valuable lessons. We are integrating their methods—such as simulation-based testing, digital twins, and Hardware-in-the-Loop—to enable more realistic risk analysis and increase system uptime.

Looking ahead, Artificial Intelligence is the next major step. It will enable us to analyze data in real time, predict and mitigate risks, and develop adaptive safety measures. At Mayr®, we embrace this holistic approach to create pioneering safety concepts that exceed industry standards and deliver long-term value for all stakeholders.

IU. Are there any recent developments or future technologies at Mayr® that you believe will significantly impact your customers?

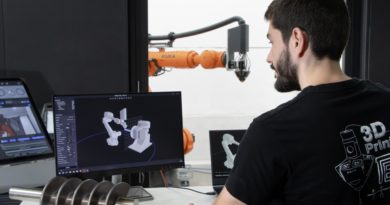

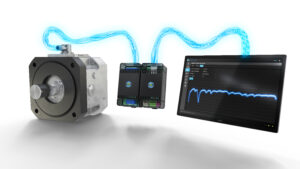

Since we are active in many different industries, we have a wide range of developments to share. In robotics and automation, for example, we are convinced that gravity-loaded axes must be fail-safe at all times. At the trade fair SPS 2025 in Nuremberg, we presented the next generation of our ROBA®-topstop® safety brakes, which enable this level of safety in smart environments. The compatible ROBA® brake-checker® module enables continuous brake monitoring. Combined with the ROBA® gateway, the system delivers valuable data for proactive machine maintenance, digital twins, and smart production environments.

Looking ahead into 2026, we will introduce new, large safety brakes for maritime applications and other heavy-duty scenarios, motor brakes for extremely high torques and many other interesting solutions. Stay tuned for more updates.

IU. How does Mayr® ensure consistent quality standards across different regions and operations?

Within just a few months of opening our new plant in Halol, we scored a hat trick: We were able to secure three international certifications concurrently. Our certifications in ISO 9001 (Quality), ISO 14001 (Environmental), and ISO 45001 (Occupational Health and Safety) speak to our commitment to the highest standards. The fact that we managed to get certified almost immediately also shows that our international processes work and that we are able to roll out the proverbial Mayr® safety, reliability and innovation everywhere on the globe.

IU. How do you approach quality and safety governance across multiple countries and production sites?

Our global strategy and diverse plant structure position us to master complexity and varying levels of technology. By using identical test benches in all our plants, we guarantee consistent, high-quality standards locally. Our guiding principle is ‘Many locations, one quality’. Every product that leaves one of our plants is tested to the same global standards, and the results are meticulously documented. This comprehensive control is the cornerstone of our quality promise.

Beyond product safety, we prioritize the well-being of our employees, fostering a vibrant culture through proactive team building and family engagement initiatives. This focus on engagement and support drives high retention and ensures a motivated, cohesive workforce—the internal engine that consistently delivers on our global quality standards.

IU. Any message would you like to convey to your customers and industry peers reading this interview?

Safety, reliability, and innovation are the core values that drive us. On this basis, we are a reliable partner for our customers. I am convinced these values will remain just as relevant in the future. We safeguard the movements of this world, and that is the purpose that drives and motivates us every day.