Mehta Group Introduces Large Format Fiber Laser Cutting Machine for Thick Metal Plate Cutting – MR SERIES

The Mehta Group has introduced its new Large Format Fiber Laser Cutting Machine, designed to support the growing demand for cutting extra-large metal sheets and thick plates with accuracy and stability. Capable of cutting MS plates up to 100 mm in thickness, the system is intended for industries such as heavy fabrication, infrastructure, shipbuilding, and energy equipment manufacturing, where precision and scale must go hand in hand.

Built on a gantry-type structure with ground rail transmission, the machine maintains rigidity and positional accuracy even across long travel distances. This structural design minimizes vibration and distortion during cutting, allowing manufacturers to achieve consistent edge quality across oversized workpieces and thick materials.

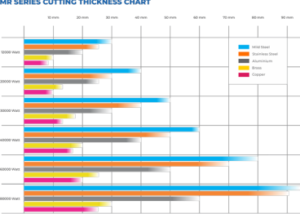

The MR Series Fiber Laser Metal Cutting Machine is available with laser power options from 12 kW, 20 kW, 30 kW, 40 kW, 60 kW, and up to 80 kW. This range allows companies to match machine capability with their specific cutting thickness and production requirements, whether they are processing medium plates or heavy industrial components.

HIGH POWER LASER SOURCE

The MR Series is equipped with a Raycus Fiber Laser Source that delivers stable beam output, high energy efficiency, and long service life. Consistent laser power is especially important when cutting thick plates, where beam stability directly impacts edge quality and cutting speed.

SAFETY PROTECTION

Safety protection curtains are installed on both the front and rear sides of the beam. If any object enters the safety zone, the system immediately triggers an emergency stop, helping protect operators and equipment during high-power cutting operations.

SEPARATE DESIGN OF WORKBENCH AND TRANSMISSION MECHANISM

The worktable and transmission system are built as separate units. This design isolates heat generated during laser cutting from the motion system, reducing thermal influence on precision components. The result is improved accuracy, better long-term stability, and extended service life under continuous heavy loads.

INTELLIGENT REUSE FACILITY

This facility allows the machine to scan multiple offcut pieces, extract contours, and support automatic or manual nesting. By improving how leftover material is reused, the system reduces waste, lowers material costs, and supports more efficient and sustainable production workflows.

ADVANCED BEVEL CUTTING TECHNOLOGY (Optional)

The optional bevel cutting system enables accurate angular cuts on thick and large metal sheets. This removes the need for secondary machining such as milling or grinding, improving productivity and reducing fabrication time while delivering better weld preparation and cleaner edges.

With the MR Series Large Format Fiber Laser Cutting Machine, the Mehta Group provides manufacturers with a practical solution for large-scale and heavy-duty metal processing. The system combines structural stability, flexible laser power options, and production-focused features to support reliable output in industrial environments.

For machine-related inquiries and business discussions, readers may connect directly with Mr. Narendra Purohit, Marketing Head at Mehta Hitech Industries Limited. He can be reached at +91 92279 85724 or via email at narendra.purohit@mehtaindia.com.